2018

Power Plant Turów project progress

| In October 2018 SINKOS continues the construction of 6 steel tanks for Power Plant Turów in Bogatynia. The material is stainless steel 316L and P235GH. Capacity varies from 150m3 up to 3000m3.Two tanks will be covered inside with rubber lining. The project is being performed in formula “Design and build”. The all tanks will be a part of desulphurization system. |

Completed pipelines and ducts

Modernization of fuel storage tanks

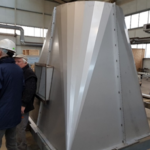

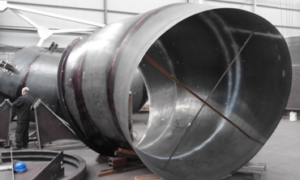

New sludge dryer for France

| In September 2018 SINKOS has started construction of new sludge dryer for a customer from France. The dryer will be made in stainless steel AIS 316L acc. to Danish technology. The unit will be equipped in belts drive, heating system and steering devices delivered from Danmark. Total weight of the dryer: over 22 T, length: over 18 m. |

Modernization of production plant Bridgestone

| In August 2018 SINKOS has completed modernization of production plant Bridgestone in Stargard. The production unit for glue for rubber have been equipped in electrical cables for steering of new valves and in new pipelines in steel 316L. The tanks for glue have been equipped in additional nozzles for filters and gauges. |

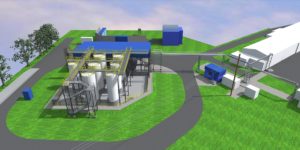

Power Plant Turów extension progress

| In April 2018 SINKOS continue the construction of 6 steel tanks for Power Plant Turów in Bogatynia. Part of tanks will be constructed in stainless steel 316L. Capacity varies from 150m3 up to 3000m3. Two objects will be cladded inside with a rubber lining. The project in being performed in formula “Design and build”. The all tanks will be a part of desulphurization system within the power plant. |

Completion of sludge dryer for France

Completion of two tanks 500m3

2017

Building permission for a paint production plant

| In December 2017 SINKOS has received from local authorities a building permit for construction of extended paint production plant Sherwin-Williams. The new part of factory consists of unloading station, tank-farm with eight tanks and pipelines together with control system network, storage house and heating-room. |

Start of new tankfarm in Turów

| In November 2017 SINKOS has started construction of first tank in Power Plant Turów. The new tank capacity 3000m3 will be the first of six others to be constructed by mid 2018. The new tank-farm consists of six objects capacity from 150 up to 3000m3. Two of the tanks will be additionally rubbered inside and insulated. The all tanks will be part of desulphurization system within the plant. |

Completed installation of steel pipelines and ducts

Extension of paint production plant, engineering completion

New contract for tanks for Power Plant

| In August 2017 SINKOS has signed a contract for engineering design and construction of number of tanks as a part of desulphurization system of Power Plant Turów. The new tank-farm consists of six units capacity from 150 up to 3000m3. Part of the tanks will be rubbered inside and insulated. The steel grade is stainless steel 316L (40%) and carbon steel (60%). |

Start of pipeline construction

| In August 2017 SINKOS has started construction of pipeline network in chemical plant Grupa Azoty SA in Police. The task is being performed in “design and build” formula. Total length of the system exceeds 3000 m, the diameter of pipes varies from DN80 up to DN250, the stainless steel grade is 304 and 316, and 10% is a special alloy steel. The completion of works is planned for December 2017. |

Start of assembly of two 500m3 tanks for demineralized water

Completed installation in chemical plant 3M in Wroclaw

Tank delivery to 3M Manufacturing Poland

| In April 2017 SINKOS has sent a stainless steel tank for new tank-farm for chemicals and alkyd resins in Polish subsidiary of 3M Manufacturing in Wroclaw. The tank consists of double bottoms and shells. It was fully designed by the manufacturer engineers of Sinkos. The design comprises storage tanks with pipelines, pumps and control devices. |